New Bats Get Early Workout

College baseball’s new look may be coming sooner than expected.

The NCAA Division I baseball committee has recommended that new bat standards, designed to limit the performance of high-powered aluminum bats, go into effect for the 1999 playoffs and College World Series.

That proposal and a controversial NCAA memo raising new questions about safety have left the Pacific 10 and Big West conferences, among others, considering using bats that meet the new standards at the start of the regular season in early February.

But, with preseason practice little more than three weeks away, uncertainty still reigns.

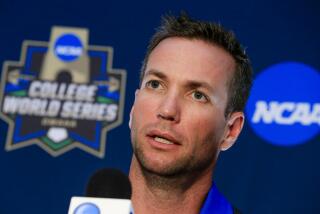

“It’s all chaos right now,” USC Coach Mike Gillespie said.

The NCAA baseball rules committee pushed for less powerful bats to restore better balance between offense and defense, as well as for safety. A record 62 home runs--14 more than the previous high in 1995--were hit in the 1998 College World Series. The average number of home runs per team per game has increased from 0.69 in 1994 to 1.06 last season.

The NCAA Executive Committee approved the change in August, but delayed the start until August 1, 1999. Later that month, however, the NCAA circulated a memo to conference and school officials urging “all necessary steps to enhance player safety” for 1999.

That apparently brought a new wave of anxiety about legal liability if a player is severely injured this season by a ball hit off one of the high-tech bats.

The Division I baseball committee reacted with a proposal that the new bat standards be implemented in time for the playoffs. That proposal is scheduled to be considered today during a conference call by the NCAA’s Championship and Competition Cabinet, according to Dennis Poppe, an NCAA championships director.

Any decision for the playoffs isn’t binding for the regular season, although it might be a bellwether for individual conferences.

“The memos saying the other bats are dangerous has put each of us in a very exposed position,” Pac-10 Commissioner Tom Hansen said. “It’s become a terrible dilemma for the conferences and the institutions.”

Richard Rockwell, the baseball committee chairman, acknowledged that liability concerns were “a chief issue” in his group’s proposal to move up the date.

“We knew that we opened up a can of worms,” Rockwell said. “There was the issue of whether the new metal bats would be ready. And how about the coaches under bat contracts? But we felt we had to take a strong stand.”

There are about 150 Division I coaches under contract to bat companies, which pay them up to $80,000 and provide free bats to their teams.

Big West coaches unanimously recommended to the conference that the old high-tech bats be used in their regular season, regardless of the rule for the playoffs.

‘We’re making a statement as to what we think is the right thing to do,” Cal State Fullerton Coach George Horton said.

“If we thought there was a serious safety issue with the old bats, the coaches in our conference wouldn’t have voted as we did. If I thought our players were in danger, the bat companies couldn’t pay me enough or throw enough money at our program for us to do that.”

Pac-10 coaches have had similar discussions.

Hansen said he plans to poll the Pac-10 Council of athletic directors, senior women administrators and faculty representatives the same day as the NCAA vote.

Big West Commissioner Dennis Farrell said he also plans to poll school officials.

The West Coast Conference had announced that its teams would use wooden, wood composite or NCAA-certified aluminum bats in the coming season, but Friday suspended those restrictions pending further evidence on bat safety, according to assistant commissioner Don Ott.

Easton Sports has sued the NCAA for $267 million, charging restraint of trade.

“I think the least [the NCAA] could do is abide by their executive committee’s original decision [on the effective date],” said Jim Easton, chairman of Easton Sports, a leading manufacturer of aluminum bats.

Marty Archer, president of the Louisville Slugger division of Hillerich & Bradsby, said he has been reluctant to predict when his company can meet the new standards because of the uncertainty that has surrounded testing.

(BEGIN TEXT OF INFOBOX / INFOGRAPHIC)

Driving Us Batty

In 1972, all colleges began using aluminum bats because they didn’t break like wood bats and were more cost effective. Now the NCAA is recommending changes to metal bats to make them safer and perform more like wood bats.

Wooden

Weight: 31-33 ounces for a 34” bat.

Swing: Has more momentum than aluminum bat at same speed.

Handle: Flexes when ball hits.

3.8” sweet spot: The ‘sweet spot’ is point where flexing is canceled and maximum energy is retained by ball.

Aluminum

Weight: 29 ounces for 34” bat.

Swing: Faster than wood bat.

Handle: Less elastic, cuts down flex. More energy retained by ball.

4.2” sweet spot: Has larger sweet spot, closer to knob of bat.

New Specifications for Aluminum Bats

Length-to-width differential reduced from five to three

Example: for a 34” bat:

Current minimum weight: 29 ounces

New minimum weight: 31 ounces.

Batted ball exit speed: No more than 93 mph. Previously, speed was unlimited.

Maximum diameter decreased:

Previous diameter: 2 3/4”

New diameter: 2 5/8”

*

Sources: Easton Sports; NCAA; Chang Choi, Ken Conley, Joe Giuliani, ThinkQuest

More to Read

Go beyond the scoreboard

Get the latest on L.A.'s teams in the daily Sports Report newsletter.

You may occasionally receive promotional content from the Los Angeles Times.